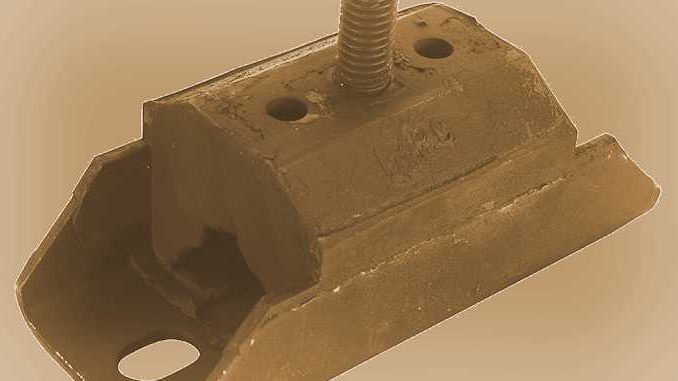

In the pursuit of improving the way cars are built, the automotive industry introduced several applications that are out of plain sight but have proven to be quite effective given their respective purpose. One such example of often ignored parts is the transmission mount.

The device has three purposes, one of which is to serve as the connection between the transmission and the chassis.

The second function of the transmission mount is to control the torque and vibration of the vehicle’s driveline. Vibrations can be annoying to the driver and are a possible distraction or an obstacle in controlling the vehicle. Limiting vibrations also preserve the mechanical parts’ structural integrity. Transmission mounts work hand in hand with engine mounts to minimize vibrations.

The third function of the transmission mount is to ensure that the angles of linkages and the driveshaft are correct. It also forms the rear support for the transmission. If the angle of the driveshaft is out of place, it could cause a loss in power.

How To Diagnose A Bad Transmission Mount Or Motor Mount

Rubber and steel are the most commonly used materials for transmission mounts. Due to rubbers vulnerability to outside elements as well as to time itself, the transmission mount will eventually require replacement.

Otherwise, a broken transmission mount can prove to be more expensive should one fail to notice the symptoms. Symptoms such as increased vibration and noise of the vehicle.

Other than the audio annoyance, accelerated deterioration of the cross pieces and universal joint yokes are to be expected.

In some rare cases, a broken transmission mount could lead to leaks in the exhaust pipes or holes on the radiator.