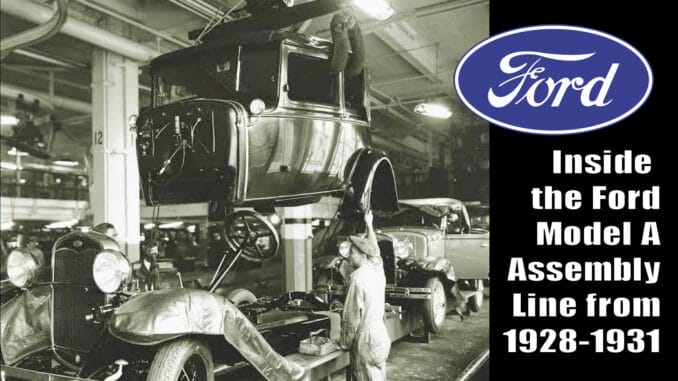

From raw materials to the open road, the iconic Model A Ford’s manufacturing process was a meticulously orchestrated production symphony. From 1928 to 1931, nearly 5 million Model A Fords rolled off assembly lines across the globe. This captivating compilation video delves into the heart of the production process, uncovering the intricate steps that brought these legendary automobiles to life.

Exploring the Model A Ford Assembly Line

Building the Foundation (00:00 – 09:45)

The journey begins with the creation of the engine, where sand molds are meticulously crafted, engine blocks are cast, and components are machined with precision. From pouring babbitt to forging and balancing crankshafts, each step is essential in laying the groundwork for the Model A’s powerhouse.

Crafting the Body (10:44 – 22:50)

As the engine takes shape, attention turns to the vehicle’s body. From wheel production to stamping sheet metal, the outer shell of the Model A starts to emerge. Intricate processes like body jig assembly and wet sanding ensure every curve is perfect before painting and pinstriping add the finishing touches.

Interior Excellence (19:10 – 22:50)

No detail is overlooked in the interior production of the Model A. From crafting glass to upholstery manufacturing, every element contributes to the comfort and style of the finished product.

Final Touches and Beyond (22:50 – 26:51)

With the body and interior complete, the Model A undergoes final preparations before being driven off the assembly line, ready to conquer the open road. Every step from testing engines to balancing wheels is taken to ensure the utmost quality and performance.