Adding an aftermarket transmission cooler to your hot rod, car or truck is always a good idea. Here are some tips:

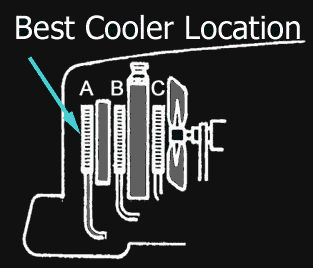

Always mount the cooler in a place that has good air flow

- If you are mounting it in front of the radiator, always make sure the fin’s in the cooler are parallel with the fin’s in the radiator. This prevents restricting air flow to the radiator.

If you place the cooler in and area with little air flow, a fan is a must

When installing coolers, make sure lines are clear of anything that can rub them

Always use line that is approved for transmission/hydraulic fluid

- Fuel line will not work and will break down in transmission fluid.

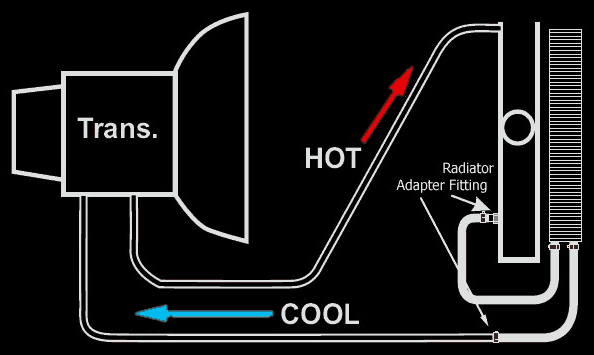

Bypassing the radiator is the way we prefer a cooler be set up. The transmission will generally run cooler this way

- Additionally, this may take some of the load off the radiators job of cooling the engine.

When hooking up multiple coolers several things should be noted

- The cooler itself is a restriction of flow and this restriction while not a problem for the cooling or lube to the transmission can cause excessive pressure inside the converter. This can force the converter against the flex plate more so than normal and cause wear to the engine thrust bearing. A stopped up or severely restricted cooler or cooler lines can do the same.

- When installing more than one cooler, its advised to put them in parallel with each other, This means one line from the transmission is split with a Y and one line run to each cooler then out of each and into a Y back to a single line running to the transmission. This will assure adequate cooling while reducing the wear to the engine thrust bearing.

- Always use line that’s at least as large as the inlets in the cooler, Avoid extreme twist or turns in them particularly with rubber lines.

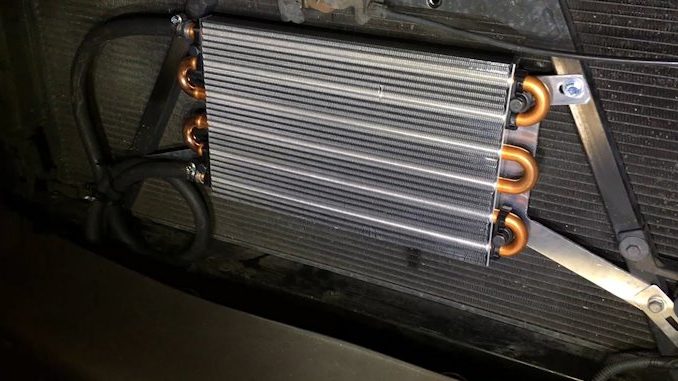

Type and brands of coolers

- We really have no preference here as far as brand. From our experience, an expensive brand name unit or a generic one seem to do the same job.

- We have found the stacked plate (flat tube) types tend to be more efficient in the same dimensional sizes with a greater temperature drop.

Always be sure that the metal lines coming from the transmission under car do not contact the headers or exhaust

- This is not specifically about a cooler but about cooling. If the cooler lines were in contact with the headers, it would super heat the fluid when the headers get hot. Make sure there is no contact so you won’t have a problem.

- Always keep transmission cooler lines factory or otherwise as far away from the exhaust as possible.

Transmission temperatures – This question gets asked a lot. What’s TOO HOT?

- Well, ideally you want your average temperature to stay under 190 degrees. However, we would not get too concerned until the temperature gets to or over 230 degrees.

- Heat can damage a transmission by breaking down the fluid and causing rubber seals to harden and break.

Never attempt to remove fluid from your transmission by starting the engine

Never attempt to flush by catching fluid in a pan while adding fluid in the dipstick hole

- When this is done, no lube is being sent to the gears and bushings. They can go dry and melt down very quickly, destroying or significantly shortening the life of your transmission.

It is advisable to fully and properly flush a cooler, especially when a converter failure is involved

- A transmission internal failure is unlikely to put debris in the cooler, because all fluid coming from the transmission must travel through the trans filter.

- Its always a good idea to power flush a cooler or replace it after a failure. It is particularly important in the type of failure. Anything that’s in your cooler or lines will end up in your valve body, bushings and gears.

- A cooler cannot be properly cleaned simply by blowing air through it. A can of cooler flush, which most shops have, followed by being blown out with air is the correct way to do it.

When installing rubber cooler lines to metal lines always put a small flair at the end of the metal line

- Not too big because you will tear the line on the inside during install. Then place a clamp just ahead of the flair.

- Roughening up the outer surface of the metal line with coarse sand paper in the area where the clamp will ride will help assure a good seal and reduce the possibility of blow off.

- Never over tighten clamps to the point of the rubber oozing through or being cut this will cause a failure too.

The best place for temperature sending units is in the pan

- This is because it will give the best average temperature which is what’s important.

- Using the pressure port is OK, however, you will show temps 10 to 20 degrees higher than in the pan.

- We do not suggest placing temp senders in either the inlet or outlet from the cooler. This is because it will increase cooler restriction and increase the odds of a leak.

Diagram: Best Transmission Cooler Placement