This site contains affiliate links for which we may be compensated.

Welding Basics

We explore the benefits of removing the nozzle for flux core welding and discuss the exceptions where it is necessary.

[More…]

How To & DIY

From polarity to tension and stick-out, we’ll cover the key elements that contribute to successful welding with self-shielded flux core wire.

[More…]

How To & DIY

How to clean your MIG torch, why it’s important, what build-up does to the wire tip, and how it makes the entire welding process easier.

[More…]

How To & DIY

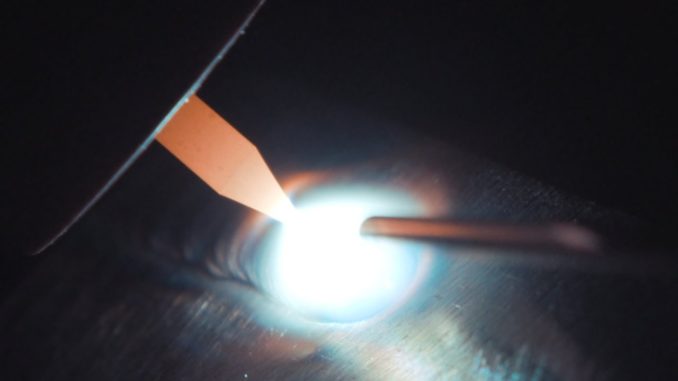

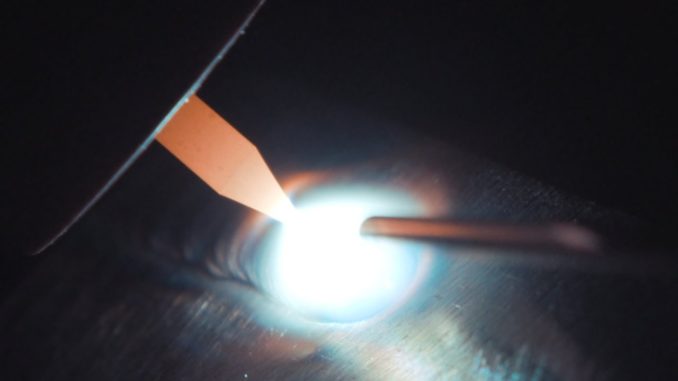

Karl shows you how to gas weld with an oxy-acetylene torch including techniques, tips, and a step-by-step tutorial on both fusion and filler.

[More…]

Welding Basics

Taking the time to find the right helmet for your needs can increase your productivity and weld quality, as well as your comfort…

[More…]

Welding Basics

Joe goes over the three basic MIG welds — stitch weld, plug weld, and normal weld — that you should know when working on a project vehicle.

[More…]

Welding Basics

When learning to weld or working a metal fabrication project, one of the first questions is “Where do you buy material for welding projects?”

[More…]

How To & DIY

Chicago Electric Flux Core 125 Welder from Harbor Freight is used to weld an automotive patch panel into place, repairing a fender rust hole.

[More…]

How To & DIY

Several methods are demonstrated; file, die grinder, and curved flap disc, to show you how to properly deal with inside corner grinding.

[More…]

Welding Basics

Make Everything shows you a super simple mod for your welding hood that will change the way you work in dark or confined spaces!

[More…]