Cast aluminum weld repairs are difficult. Welding around a bolt hole without damaging the threads is even more difficult. Here’s how to get it done quickly and easily using a simple trick with a stainless steel bolt.

Time needed: 30 minutes

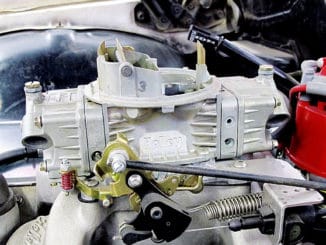

How to weld a cast aluminum bolt hole without damaging the threads.

- Clean and Degrease the area to be repaired.

Clean area to be repaired with degreaser and wire brush.

- Expose Bright Metal in cast aluminum.

Use a carbide burr tool is to fully expose the bright metal.

- Remove Debris and Final Clean area to be repaired.

Remove debris with compressed air and rinse area with acetone.

- Pre-Heat with Torch

This provides a mild pre-heat and ensures all grease and oils are cooked away.

- Set Stainless Steel Bolt

Thread Stainless Steel bolt into threaded area to be repaired.

- Make the Weld Repair

Execute the repair, fully demonstrated in the video below…

How to weld a cast aluminum bolt hole without damaging the threads demonstrated and clearly explained by The Fabrication Series from start-to-finish…

Knowing this quick Stainless steel bolt trick will probably save you on your next repair job!