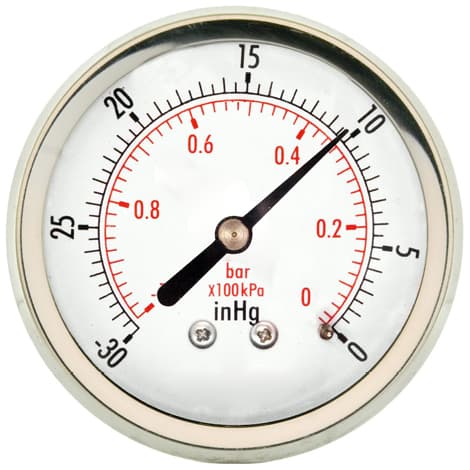

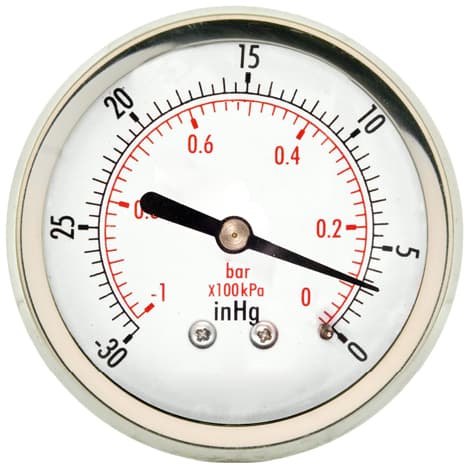

Vacuum gauges have been a valuable tool to mechanics for years, and one of the easiest and cheapest ways to check an engine for serious issues is to perform a vacuum gauge test.

Even with modern computer-controlled engines, a vacuum gauge is still a valuable tool for diagnosing engine and transmission problems. You can determine whether or not an engine is healthy in just several minutes.

Vacuum Gauge Engine Testing

A vacuum test shows the difference between outside atmospheric pressure and the amount of vacuum present in the intake manifold. Piston rings, valves, ignition system, and the fuel system all affect how much vacuum is created, as well as other parts that may affect the combustion process (emissions devices, etc.).

Each has a characteristic effect on the running of the engine and you judge performance/problems by watching variations from normal. It is important to judge engine performance by the general location and action of the needle on a vacuum gauge, rather than by a single reading.

Evaluate performance by watching variations from normal. It is important to evaluate engine performance by the general location and action of the vacuum gauge rather than just by a vacuum reading itself. A vacuum gauge can help determine engine state or problems, including the following:

Normal Engine Operation

At idle, an engine should show a steady vacuum reading between 17″ and 21″. A quick opening and closing of the throttle should cause the vacuum to drop below 5″ then rebound to 21″, or more.

General Ignition Issues or Sticky Valves

With the engine idling, continued fluctuation of 1 to 2 inches may indicate an ignition problem. Check the spark plugs, spark plug gap, primary ignition circuit, high tension cables, distributor cap, or ignition coil. Fluctuations of 3 to 4 inches may indicate sticky valves.

Intake System Leakage, Valve Timing, or Low Compression

Vacuum readings at idle that are much lower than normal can indicate leaky intake manifold gaskets, manifold-to-carburetor gaskets, vacuum brakes, or the vacuum modulator. Low readings could also be very late valve timing or worn piston rings.

Exhaust Back Pressure

Starting with the engine at idle, slowly increase engine speed to 3,000 RPM, engine vacuum should be equal to or higher than idle vacuum at 3,000 RPM. If vacuum decreases at higher engine RPMs, excessive exhaust backpressure is likely present.

Cylinder Head Gasket Leakage

With the engine Idling, the vacuum gauge indicator will sharply drop every time the leak occurs. The drop will be from the steady reading shown by the pointer to a reading of 10″ to 12″, or less. If the leak Is between two cylinders, the drop will be much greater. Determine the location of the leak by performing a compression test.

Fuel Control System Troubles

All other systems in an engine must be functioning properly before you check the fuel control system as a cause for poor engine performance. If the pointer has a slow floating motion of 4 to 5 inches – you should check the fuel control.

A Note About Diagnosing Transmission Problems

An important part of transmission diagnosis is to make certain the engine operates properly. If the engine performance is incorrect, the transmission will receive the wrong information. Many times what is perceived as a transmission problem is actually an engine problem.

The engine sends signals to the transmission through a vacuum line, throttle cable, or both. These signals basically synchronize torque with transmission line pressure, shift feel, and shift timing. Malfunctions in items like the air filter; spark plugs, EGR valves, and other parts of the fuel, electrical, and emission systems could result in improper transmission performance.

How To Connect a Vacuum Gauge and Perform a Vacuum Test

To check manifold pressure with a vacuum gauge, you will need to locate a port in the manifold or throttle body. Manufacturers install ports on their manifolds for the Brake Booster, PCV tube, EGR Switch, A/C vents, etc. Find one for the vacuum gauge line to be inserted into firmly.

NOTE: Vacuum readings will vary according to the altitude in different localities. From sea level to 2,000 feet elevation all normal engines should show a vacuum reading between 17 to 21 inches. Above 2,000 feet elevation, the vacuum reading will be about one (1) inch lower per each 1,000 feet rise in elevation.

Vacuum Gauge Readings and Meanings

Normal Motor

Needle steady between 17 and 21

Normal Motor

Open and close throttle rapidly rings and valves are OK

Poor Rings or Oil

Needle steady but lower than normal

Poor Rings or Oil

Open and close throttle rapidly needle pulls down to zero

Sticky Valve

Needle drops occasionally about 4 divisions

Burnt Valve

Needle drops regularly several divisions

Leaky Valve

Needle drops 2 or more divisions when valve should close

Loose Valve Guide

Fast fluctuation of needle between 14 and 19

Weak Valve Guides

Motor racing, needle registers 10 to 22, variations increase with RPM

Late Valve Timing

Needle reads between 8 and 15 and remains steady

Late Ignition Timing

Needle reads between 14 and 17 and remains steady

Plug Gap Too Close or Points Not Syncronyzed

Needle foats slowly between 14 and 17

Leaky Intake or Carburetor Gasket

Needle reads below 5

Leaky Head Gasket Between Cylinders

Needle floats between 5 and 19

Choked Exhaust/Muffler

High reading at first, breaks to 0 and builds back to 16

Carburetor Out of Adjustment

Needle slowly floats between 13 and 17

Vacuum Gauge Engine Condition Indicators

| Engine Speed | Vacuum Gauge Reading | Indication of Engine Condition |

|---|---|---|

| Smooth and steady idle (800 to 1200 RPM) | Between 17 to 21 inches | The engine is in Good Condition, but perform the next test to be sure. |

| Open and close throttle quickly | Jumps from 2 to about 25 inches | The engine is in Good Condition. |

| Smooth and steady idle | Steady, but lower than normal reading | Worn rings, but perform the next test to be sure. |

| Open and close throttle quickly | Jumps from 0 to 22 inches | Confirms worn rings. |

| Steady idle | Intermittent dropping back 3 or 5 divisions and returns to normal | Sticky Valves. If injection of penetrating oil into intake manifold temporarily stops pointer from dropping back, it’s certain the valves are sticking. |

| Steady 3000 RPM | Pointer fluctuates rapidly, faster engine speed causes more pointer swing | Weak valve springs. |

| Steady idle | Fast fluctuation between 14 to 19 points | Worn intake valve stem guides. Excessive pointer vibration at all speeds indicates a leaky head gasket. |

| Steady idle | Constant drop | Burnt valve or insufficient tappet clearance holding valve partly open or a spark plug occasionally miss firing. |

| Steady idle | Steady 8 to 14 inches | Incorrect valve timing. It must also be remembered that vacuum leaks and/or poor compression can result in a low vacuum reading. |

| Steady idle | Steady 14 to 16 inches | Incorrect ignition timing. |

| Steady idle | Drifting from 14 to 16 inches | Plug gaps too close or points not synchronized. |

| Steady idle | Drifting 5 to 19 inches | Compression leak between cylinders. |

| Steady idle | Steady below 5 inches | Leaky manifold or carburetor gasket, or stuck manifold heat control valve. |

| Steady idle | Floats slowly between 12 and 16 inches | Carburetor out of adjustment. |

| Blipping engine speed | Quick drop to zero then return to normal reading | The muffler is clear. |

| Blipping engine speed | Slow drop of pointer then slow return to normal reading | The muffler is choked or blocked. |

Inexpensive Vaccum Gauge Test Kits Available on Amazon

Conclusion

A vacuum gauge test will help pinpoint the source of automotive mechanical problems at a low cost and in a short time. The results of a well-performed vacuum gauge test will guide you to specific systems and components for further testing if needed.

The vacuum gauge has been replaced as one of the primary tools in a shop by newer technology — but don’t underestimate its value and effectiveness. The vacuum gauge still remains a reliable tool for many shops and wise Do-It-Yourselfers that know how to take advantage of it.