The hand file is such a standard tool that you’ve probably used one at some point.

In the past, we’ve corrected fabricators in our shop about file usage, explaining that dragging the file on the backstroke will dull the file, thus shortening its life, especially when filing various metals. Then we happened across a very interesting, thorough, and well-executed tool test performed by YouTuber Jason Marburger of Fireball Tool.

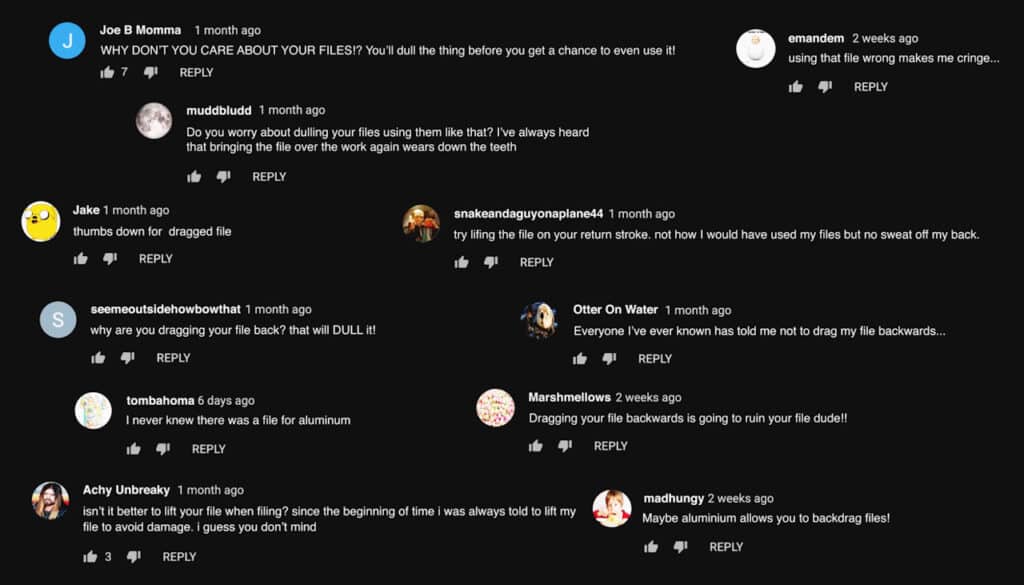

Jason noted that viewers had filled his comment section with many comments roasting him for how he used a file in a recent video.

After so many comments about using a metal file correctly, Jason did some research and noted that the Internet tells him that dragging the file is wrong, as are all of the textbooks.

But he found this pretty strange, as nobody says to lift on a backstroke when using a die file machine, or a hacksaw, or even a Sawzall (reciprocating saw) — and all of these have cutting blades with teeth facing in one direction.

Filing Using the Lift Method

Proper textbook filing looks something like this: as you’re pushing forward, the teeth do all the cutting, then lift the file off of the material and reset for the next cut.

Filing Using the Drag Method

The file never leaves the work; the file gets reset by a lightweight drag motion.

Conventional Knowledge of Metal File Use and Technique

Most people use hand files incorrectly — a file should not be used in a sawing motion (pressing back and forth), but rather pushed forward and then lifted off the workpiece on each stroke.

The cutting teeth on a file or forward-facing, which means they work only when the file is moving in that direction. Drawing a file back against the workpiece can bend the teeth and permanently damage the tool — and files cannot be sharpened. However, they should be cleaned regularly using a file card, which is a particular kind of wire brush.

There are other types of strokes like draw filing that push the file in a sideways motion to create a finer shaving. Just remember to never pull back on the file only push it forward.

Jason decided that he wanted to learn more about back-dragging a file, and in one of the most comprehensive tool usage technique tests we’ve seen, he created the ultimate file testing machine.

Building the Ultimate Machine To Test Lifting and Dragging a Metal File

After receiving all those spiteful comments for back-dragging his file and researching why it is frowned upon, Jason proceeded to build the most giant, most accurate file testing machine. Using his 36″ Cincinnati Shaper to perform tens of thousands of perfect strokes as he put files and filing techniques to the test.

Skip to the actual file tests and results…

Does Back-Dragging Dull a Metal Hand File?

Jason Marburger of Fireball Tool tests to see if back-dragging dulls a file like so many claim.

He tests coarse, medium, and fine machinist files (Pherd brand) with an extensive testing rig to stroke the files tens of thousands of times on hot-rolled steel coupons. Each steel coupon is 3/4″ X 3/4″ (19mm X 19MM).

He also tests to determine if back-dragging unclogs the files during use with a slow-motion camera to analyze the results and uses a microscope to observe what damage and wear occur to each of the files tested.

Machinist File Lift vs. Drag Test Results

| Pherd File Tested | Lift Method | Drag Method | Drag Method Only | Drag/Lift Methods |

| Coarse Metal File | .782 inches 19.9 mm | .803 inches 20.4 mm | ||

| Medium Metal File | .526 inches 13.4 mm | .735 inches 18.7 mm | .164 inches 4.2 mm | .515 inches 13.1 mm |

| Fine Metal File | .462 inches 11.7 mm | .558 inches 14.2 mm |

Conclusion

The Drag method removed more material using the Coarse file by .021″ (.5 mm), Medium File by .209″ (5.3 mm), Fine file by .096″ (2.5 mm). The back-dragging technique doesn’t appear to be detrimental to the tool by studying the close-up photos and is ultimately more effective. Go figure.