Oil filters play a crucial role in maintaining engine performance and longevity by removing contaminants and impurities from the oil. However, striking the right balance between filtering capacity and oil flow restriction can be challenging. In this article, Brand Ranks will test various oil filters to determine their restrictiveness and filtering efficiency.

Testing Oil Filter Restriction

To evaluate the restrictiveness of oil filters, a pressure gauge was employed. Higher pressure readings indicated greater restriction. Four contenders were tested: Mobil 1 Extended Performance, FRAM Ultra Synthetic, K&N Select, and Walmart’s Premium SuperTech.

Filtering Efficiency Assessment

The filtering efficiency of the oil filters was examined through a meticulous process. Identical samples of used oil were carefully mixed and divided into separate containers. Each filter was installed, and the corresponding oil sample was added. A pump was run continuously for 10 hours to simulate real-world conditions.

Following the completion of the tests, approximately 3 oz. of used oil samples were collected and sent to an oil testing laboratory for analysis. This analysis would provide accurate insights into the effectiveness of each filter in removing impurities and contaminants from the oil.

Understanding Oil Filter Components

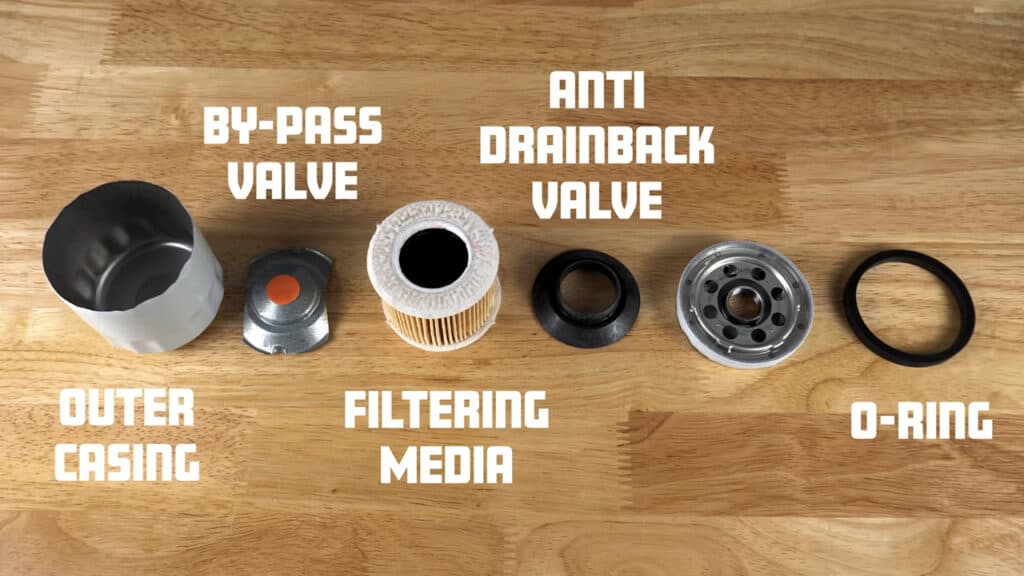

Oil filters typically consist of five components: the outer casing, o-ring, filter media, anti-drain back valve, and bypass valve. In normal operating conditions, contaminated oil enters the filter through the outer perimeter and flows through the pleated filtering media. The filter collects contaminants, allowing clean oil to return to the engine through the center. The anti-drain back valve ensures that oil flows in only one direction, preventing draining back to the oil pan during engine shutdown.

Some filters also feature a bypass valve located at the filter’s bottom. This valve remains closed under normal conditions but opens at a specified pressure. If the oil is too viscous in low temperatures or the filter becomes clogged, the bypass valve allows unfiltered oil to bypass the filter and reach the engine.

Testing Filter Capacity

To assess the capacity of each filter, 30-micron aluminum powder was used, the same size claimed to be filtered by most oil filters at a 99% rate. The test involved measuring the amount of aluminum powder each filter could hold before the oil flow decreased from 9 liters per minute to 8 liters per minute, and subsequently to 7.5 liters per minute.

Striking the Balance

It is important to consider the trade-off between oil restriction and filtering capacity when choosing an oil filter. Higher filtering capacity is desirable as it can remove more contaminants from the oil. However, a filter with high capacity may also be more restrictive, potentially compromising engine efficiency and performance.

Individual Needs and Considerations

Choosing the best oil filter for your vehicle depends on your specific requirements. If engine performance and efficiency are priorities, selecting a less restrictive filter may be beneficial. However, if you aim to ensure a clean engine and extend its lifespan, opting for a filter with higher filtering capacity, even if more restrictive, may be preferred.

Conclusion

Oil filters play a critical role in maintaining engine health, and finding the right balance between restrictiveness and filtering efficiency is essential. Through comprehensive testing, it is possible to evaluate the performance of various oil filters and determine which one suits your specific needs. Prioritize your engine’s requirements, and consider both restrictiveness and filtering capacity when making an informed decision about the best oil filter for your vehicle.