This site contains affiliate links for which we may be compensated.

Welding Basics

We explore the benefits of removing the nozzle for flux core welding and discuss the exceptions where it is necessary.

[More…]

How To & DIY

From polarity to tension and stick-out, we’ll cover the key elements that contribute to successful welding with self-shielded flux core wire.

[More…]

How To & DIY

Chicago Electric Flux Core 125 Welder from Harbor Freight is used to weld an automotive patch panel into place, repairing a fender rust hole.

[More…]

How To & DIY

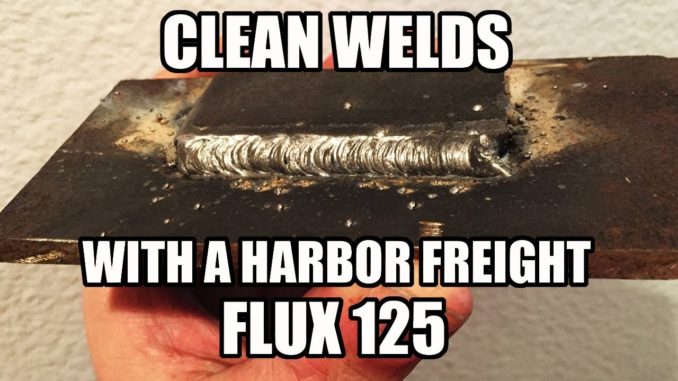

Two amateurs learn to weld with a $100 Harbor Freight Flux 125 flux core welder.

[More…]

Welding Basics

Flux-Cored Arc Welding (FCAW) is a semi-automatic or automatic arc welding process. Weld.com debunks common myths about flux-core welding.

[More…]

Products & Reviews

Wranglerstar tests the cheapest MIG welder on Amazon. This benchtop wire-feed welder includes everything needed to fabricate small projects.

[More…]

Products & Reviews

Taylor Ray performs multiple tests and practical application projects comparing a $90 Harbor Freight Welder to a $2,000 Everlast Welder.

[More…]

Welding Basics

This video offers five solid tips to help you improve your flux-core welding skills and results.

[More…]

How To & DIY

Welding common joints using a flux core MIG welder – introduces you to the types of welds involved, and demonstrates how they are produced.

[More…]

How To & DIY

The Flux 125 welder can weld mild steel from 18 gauge up to 3/16in. thick which makes it ideal for jobs around the yard, shop, or house.

[More…]