Here’s everything that you need to know when starting out with Shielded Metal Arc Welding (SMAW), more commonly known as stick welding.

This video covers:

- welders,

- welding electrodes,

- safety gear and equipment,

- striking an arc,

- tacking, and

- proper welding technique.

What Is SMAW?

Shielded metal arc welding (SMAW) also known as stick welding, is a manual process using a flux coated consumable electrode with a metal rod at the core.

Alternating current or direct current forms an arc between the electrode and the base metal creates the required heat. The flux coating disintegrates and gives off vapors that serve as a shielding gas and provides a protective layer of slag.

Both protect the weld area from atmospheric contamination. As the metal rod inside the electrode melts it forms a molten pool which becomes the weld.

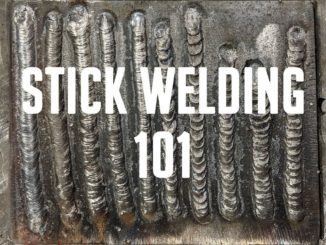

There are several variables the welder can control that will impact the width and height of the weld bead, the penetration of the weld and the quantity of spatter.

Stick welding is inexpensive when compared with other methods such as TIG. It is portable and works with any thickness and in any position.

The major downside is the slag created during the welding process along with slower speeds (unless you are highly skilled).