Project: Engine Swap, Firewall, and Floor Fix

After another shop’s botched engine swap, we were asked to pull the engine and fix the firewall, floor and get the car running again. Both an old and a new harness needed to be sorted out and correctly wired.

With the firewall work that needs to be done, it made sense to pull the front clip and get it fully out of the way.

We leave the hood in place. If you’ve ever tried to align a front end like this, you’ll understand.

When the Plymouth arrived at the shop, we noted an interesting hybrid of old and new wiring harness, both cut. In the end, we opted for a fresh 21 circuit universal wiring harness.

Some of the crazy cuts that were made to initially get this engine to fit the first time this engine was attempted to be installed.

Out comes the engine and transmission so we can work the areas around it.

The firewall was cut out to somewhat uniform, and the initial panel tacked in to place.

And the firewall patched back together and fully welded. This will get lightly skimmed with filler, but not blocked or overworked. Some “character” will be left in the metal as it will better match the inner fenders and other close surfaces.

Lightly skimmed with filler, palm-sanded, primed and sprayed with satin black. The satin black will be rubbed with compound towards completion of the project to give it a rubbed and worn surface.

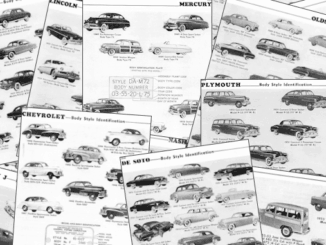

The Body Number Tag, stripped and brushed…

The floor and transmission cover have been reworked and the shifter pokes through nicely.

Getting the wiring squared away…

Fresh fuel lines and brakes lines made good sense for this Plymouth.