Ben from Rotter’s Garage bought a 1928 Ford Model A Coupe — This gem was being displayed as yard art!

Before this coupe became yard art roughly eight years ago, Ben was told it sat out in the woods of Wisconsin since the ’60s and that was confirmed since there were still 1960 tags on the car.

While loading the Model A onto the trailer, he realized the engine still turned over a bit which begs the question:

Will It Run?

Rotter’s Garage does a bit of work on a 1928 Model A Ford Coupe recently acquired through Facebook Marketplace…

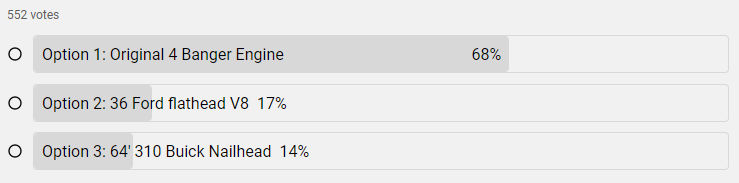

Viewers Decide How The Yard Art ’28 Model A Coupe Gets Built

Ben has been kicking around a few ideas on how to build the Yard Art 1928 Model A coupe and came up with a few different options, but right off, he promises that it will not become a rat rod…

Yard Art 28′ Model A Coupe Build

The Engine Choice Has Been Made

Ben finally got the ol’ Model A down into the shop after a couple of weeks of some much-needed shop upgrades. The first plan of attack, get those fenders out of the way, and he begins to dismantle the car…

Stripping The Body and Framing out the floors

Ben gets the rest of it’s interior components stripped out as well as the body being straightened and squared out. The construction of a new floor structure holds everything in place now, body is off the chassis, and is ready for some sandblasting…

Tearing Down The ’28 Model A’s Chassis For Sandblasting

Ben gets the complete chassis torn down to prepare for sandblasting of all parts on the Yard Art Model A. The engine, transmission, axles, and every other nut, bolt and component are removed from the frame. Everything is loaded up and brought it to the sandblasting location…

Sheet Metal Repair — Firewall and Cowl Patching

The sheet metal patching begins! Starting at the front of the car, all of the holes get filled in on the firewall, the front pillars get patched at the bottoms, and the lower cowl patches get made and installed. Ben also made a new header panel over the windshield, arched it to match the original, and welded it off into the roof line…

Stay Tuned…