Since the first GI’s returned from Europe with a hunger for cars that screamed speed and personality, chopped tops and custom louvered panels have been a staple of traditional hot rods.

Nearly 80 years later, a new generation of builders are digging up the rusted hulks of these cars and showing what can be done with simple tools, sheet metal, and little elbow grease.

One such example is the “T Wrecks” build Canadian Youtuber DD Speed Shop is working on.

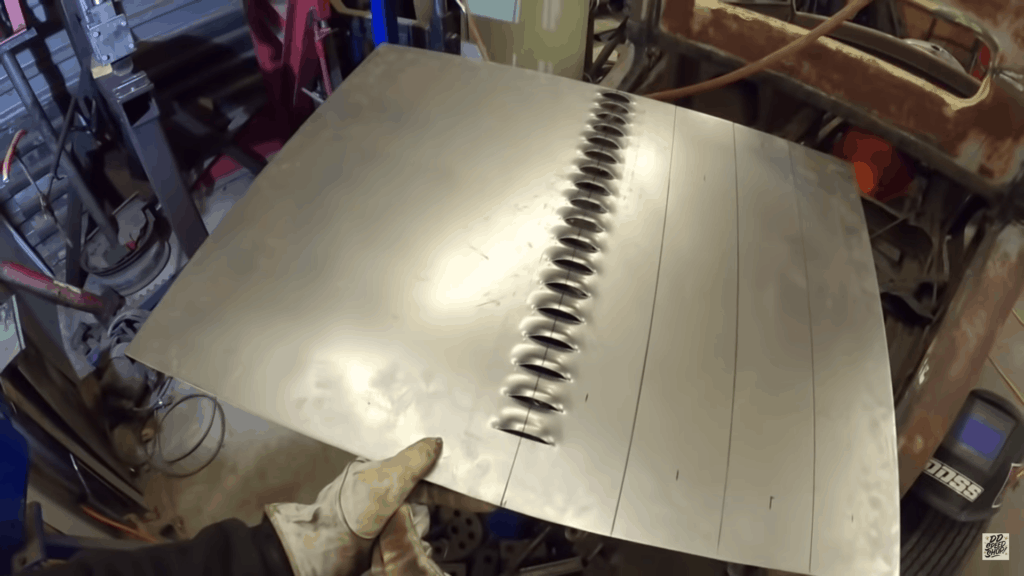

With a homemade die set, a cheap shrinker/stretcher, and a little guidance from his friend at Halfass Customs, Dan formed a new trunk lid the old school way for a ’27 Ford that was set out as yard art just a few weeks before.

It doesn’t take any laser-guided machines or a half-century of practice to form panels — with just a marker and a press, this hot rod rookie turned a few dollars in flat steel into a work of art.

As Dan is learning here, a key element of any traditional build is the personality that comes with adding elements that aren’t perfect and therefore cannot be replicated.

Another common hurdle with a traditional hot rod build is all the work finishing the chop.

There’s a little more to it than cutting a couple of inches out of the middle — as simple as they were made, pre-war cars still have tapered sections, window channels, and molding alignment to contend with.

Although it’s his first chop, Dan once again showed how quickly the chop on his ’27 T can be mastered with a grinder and a welder.

With a little ingenuity and a welder, even a total novice can build a genuinely unique hot rod with a few hundred dollars and some problem-solving.

Whether it ends up a down and dirty driver or a showroom perfect piece, we’re pretty excited to see how Dan’s first crack at a traditional style build ends up.