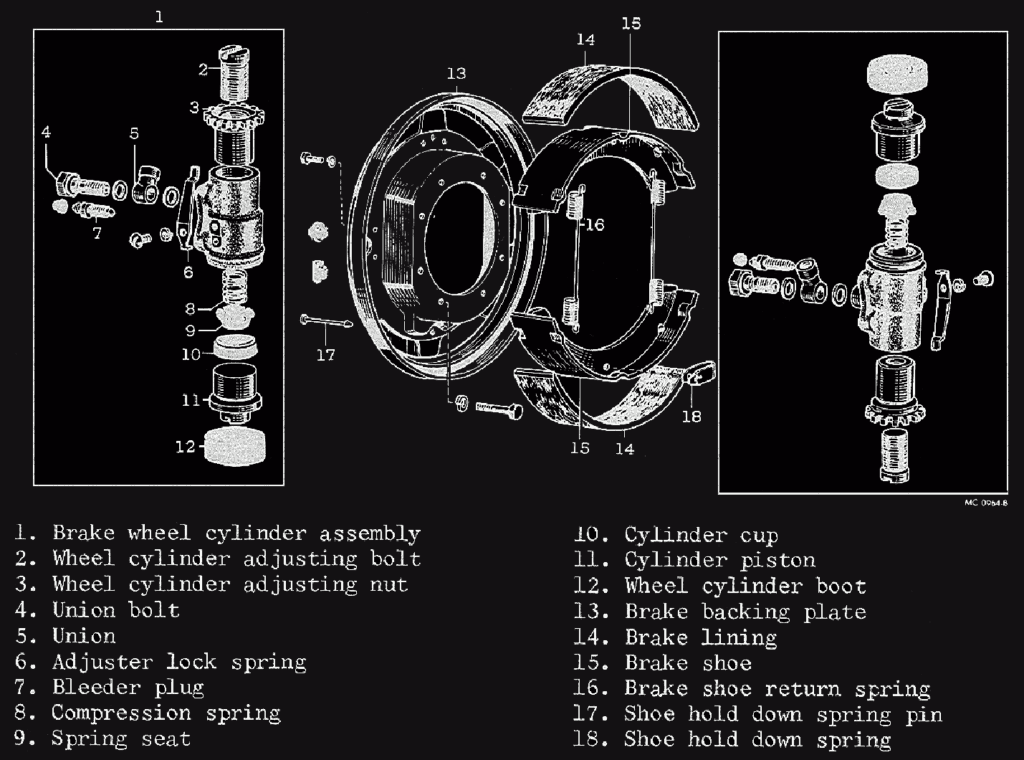

Gum and corrosion may form in the wheel cylinders if the proper brake fluid is not used. Wheel cylinders should be dismantled and examined each time the brake shoes are relined.

Leaks around the wheel cylinder pistons can be stopped by reconditioning the wheel cylinders.

Remove the pistons, rubber cups, springs, etc. and examine the interior surface of the cylinder walls.

If the walls are only slightly discolored, hone them to a mirror finish and install new rubber cups.

If the cylinder walls are deeply corroded or scored, they should be rehoned and lapped to a mirror finish or replaced with new parts.

New pistons and rubber cups should be installed in either case.

Caution: Never use a mineral solvent for cleaning hydraulic brake parts as this material would destroy the rubber parts. Use pure alcohol or brake fluid.