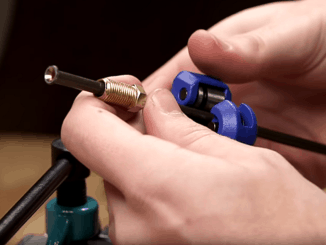

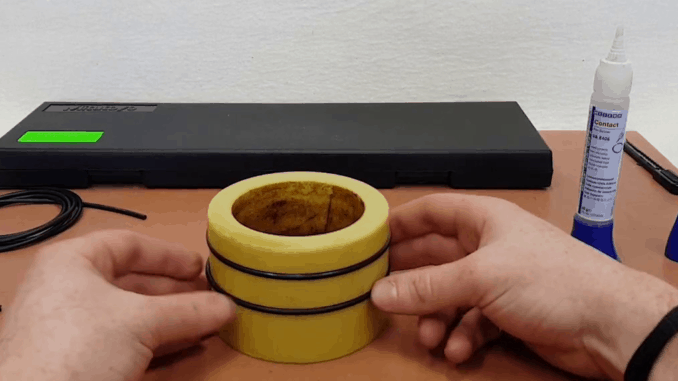

In this instructional video, you’ll learn how to measure and cut custom size O-rings. The example uses nitrile O-ring cord bonded with Weicon VA 8406 contact cyanoacrylate adhesive (Super Glue) which is good for use on almost all rubbers, except silicone.

This method can also be used to resize an over-sized O-ring when a spool of cord is not available.

Watch the video for some handy hints and tips to make sure you create a perfect fitting O-ring every time. See additional notes below…

Noted comments from the original post:

Jeremy Ardley ~ “You didn’t allow for stretch. To provide an effective seal, the O-ring’s inside diameter (I.D.) must be smaller than the piston groove diameter, so that the O-ring is slightly stretched, fitting snugly in the groove. This stretch should be between 1%-5% with 2% as the ideal in most applications.“

Mik W ~ “There has to be a more precise way of lining up the 2 ends so that they meet symmetrically. I want to make O-rings to fit in a groove within a cylinder through which a piston submerged in oil has to travel. If the join isn’t perfect I am sure it will affect the movement of the piston through the o ring seal. Hmmm…“

REPLY: Associated Gaskets ~ “Yes, getting the ends to line up perfectly is the hardest part. This method (cold-joining) is fine for producing O-rings for use in static applications. In applications such as yours, we would generally recommend using a fully molded O-ring so there would be no join at all. However, when we are cold-joining O-rings like in this video, we can also achieve more accurate joins by using a jig (a block with a recessed groove the same width as the O-ring diameter). It helps to line up the ends more accurately.“

REPLY: Mik W ~ “I agree with that. This method will obviously have its limitations where tolerances are going to be critical, but this video has made me more confident to make my own for sealing applications where there are no moving parts. The tip for calculating the circumference of the O-ring was very useful.“

About Cyanoacrylate ~ Super Glue

Cyanoacrylates are a family of strong fast-acting adhesives with industrial, medical, and household uses.

Octyl cyanoacrylate was developed to address toxicity concerns and to reduce skin irritation and allergic response. Cyanoacrylate adhesives are sometimes known generically as instant glues, power glues or super glues. The abbreviation “CA” is commonly used for industrial grade cyanoacrylate.

Cyanoacrylate adhesives have a short shelf life if not used, about one year from manufacture if unopened, and one month once opened. They have some minor toxicity.