Welding Basics

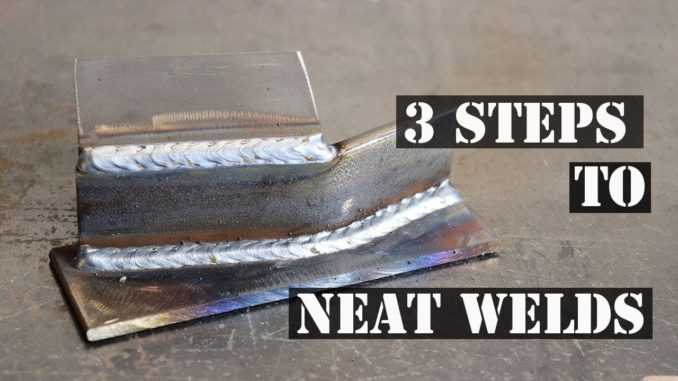

MIG Welding for Beginners ~ Three Basic Welds You Should Know

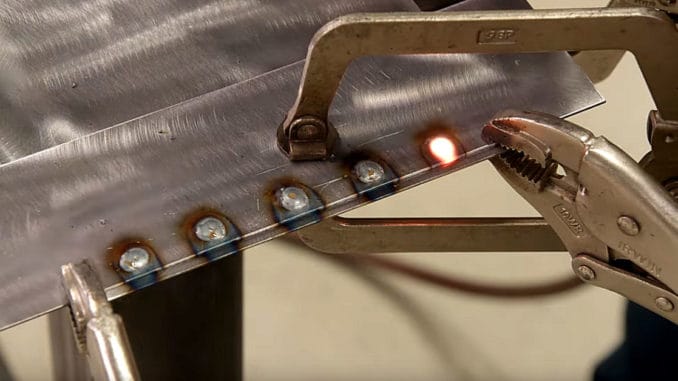

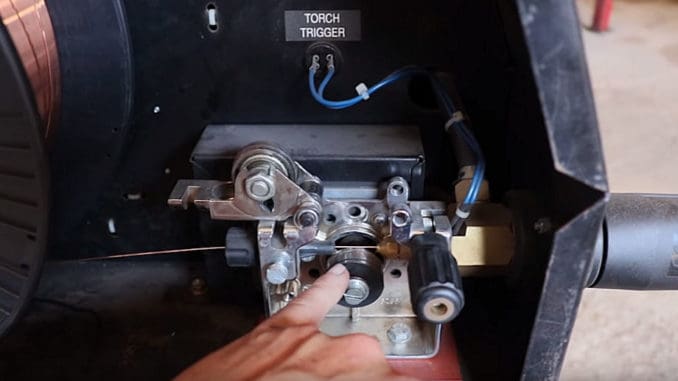

Joe goes over the three basic MIG welds — stitch weld, plug weld, and normal weld — that you should know when working on a project vehicle. [More…]

© 1996-2022 Roadkill Customs