In 1955 “Bondo” came out as the first plastic body filler and made fixing imperfections in metal much easier than before. Today fixing dents and smoothing imperfections in a body panel has been simplified to where it’s almost as “easy” as mixing two bits of putty, applying it to the panel, and sanding it all smooth.

Before those days the only option was the process of “leading”. During this process, you melt sticks made up of mostly lead and a small portion of the tin onto the surface. With the invention and evolution of plastic body fillers, the art of leading a body panel has been slowly dying out. But if you want to keep “traditional” or true to the era of the car you’re building; leading is the only way.

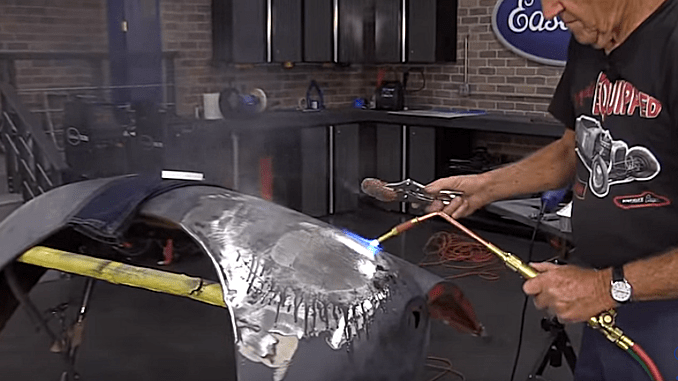

Only a few guys from the golden age of customizing and hot rodding are still with us. And even less are still working on cars. One of the best is Gene Winfield and even today, well into his 80’s he’s still traveling the world customizing old cars and teaching classes about metal shaping, leading, and anything you want to know about custom cars.

How To Lead: Leading a Body Panel with Gene Winfield

Legendary Gene Winfield stops by Eastwood to give a lesson in the lost art of leading, where heated lead is used much like body filler to smooth and fill panels.

Eastwood’s Deluxe Body Solder Kit has more of what you need to fill with better adhesion, strength, and durability than plastic fillers 30/70 lead-based body solder is slightly easier to work with than our lead-free solder and provides better adhesion, strength, and overall durability than plastic fillers.

Gene is a long-time Eastwood customer and supporter. In fact, he uses Eastwood leading supplies and claims we have some of the best products to apply lead on the market!