When engine swapping up to a fuel injected engine, there are a few things to consider when installing the exhaust…

Since the XOR team is running a fuel injected Coyote motor in the PreRunner Ranger project, the first is finding the correct location for 2 oxygen sensors and also how to weld two pieces of pipe together seamlessly.

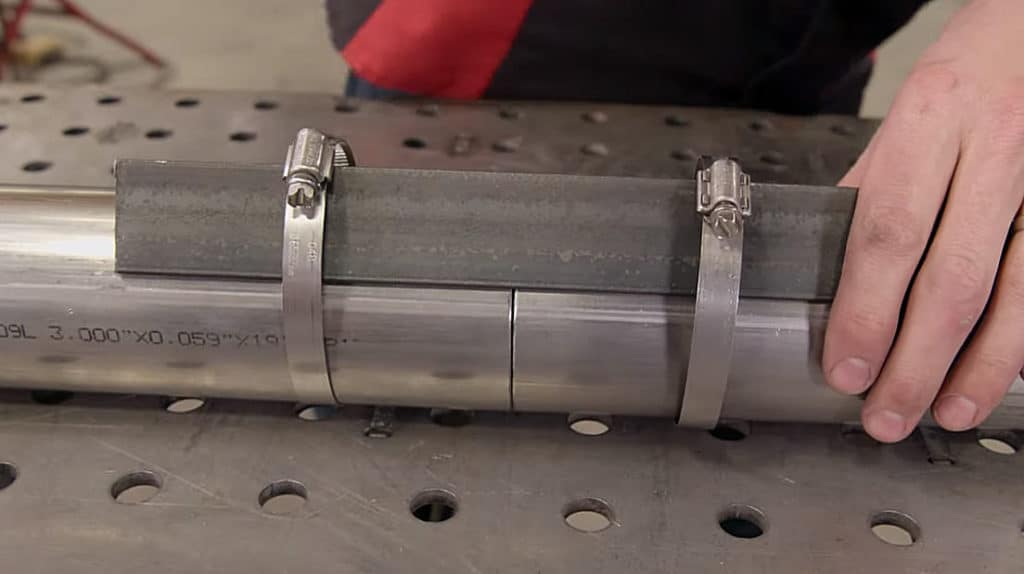

A tip for holding the pipe together perfectly straight while working under your work is to grab a piece of angle iron, slide on two hose clamps, and tighten them down…

By keeping the exhaust tube perfectly aligned, it makes welding a whole lot easier. A general rule of thumb, as the pipe size gets bigger, use a bigger piece of angle iron.

At Roadkill Customs, we’ve created a habit to keep several angle iron shorts and some thumb screw hose clamps to quickly clamp and space gaps for welding when installing exhaust.

When it comes to placing the oxygen sensors, the bung needs to be in the collector which takes the reading from all 4 of the exhaust tubes coming into the collector. Drill a hole and weld around it 100% so it seals and doesn’t throw off the reading of your oxygen sensors. Be sure to use anti-seize lubricant on the threads.

DO NOT get any anti-seize grease on the sensor head as this can damage the device.

DO NOT use any other compound, most silicon-based compounds will poison new sensors inoperative.

Torque it down to recommended specs…

- For 16 mm socket type tighten to 20 – 25 Nm (or install finger tight then 3/4 – 1 turn with a wrench)

- For 22 mm socket type tighten to 37 – 47 Nm (or Install finger tight then 1/2 – 3/4 turn with a wrench)

WARNING: DO NOT drop or use an oxygen sensor that has been dropped or mishandled as this may have caused shock damage to the ceramic cell, remember these sensors are highly sensitive electrical equipment.