The vision for this project is to build a traditional hot rod using a strong chassis that gives the car a nice stance all while utilizing some old and original parts to give the build the “soul” of a car built back in the late 1940’s-early 1950’s.

This means other than raw material used and the replacement maintenance type parts, we’ll be building it using old “stuff”.

I was going to use an original Model A frame, but by the time we straightened it (every “A” frame is tweaked or bent some), and cut it up to modify and box it, we were into more work than building a frame from scratch. I decided to build the box tubing chassis in such a manner that it’s done tastefully and doesn’t stick out like a sore thumb.

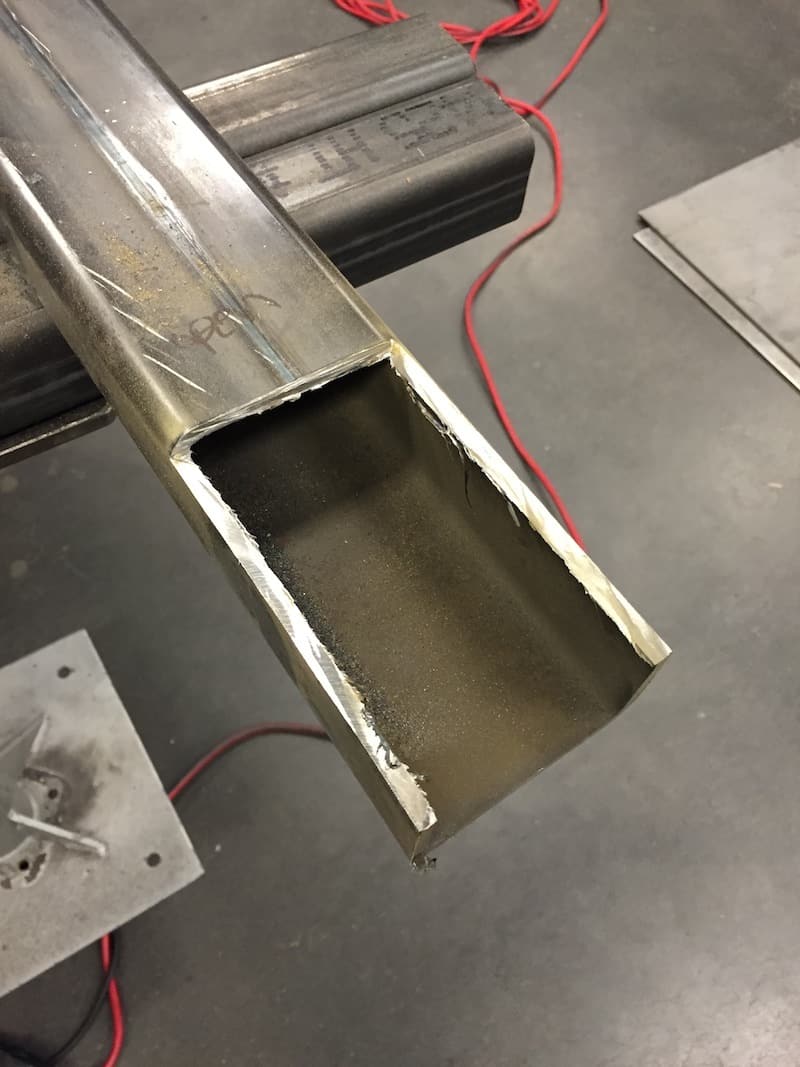

I started by ordering up some 3″ x 2″ x 1/4″ box tubing for the frame rails and rough-cut two pieces to length.

For my build, the 1/4″ wall thickness was probably overkill, but I decided to use it for diversity in case I ever wanted to change the drivetrain to something larger and heavier.

Also, the heavier tubing has a more gentle curve on the outside of the tubing that I like better. If you’re building something lighter weight like a Model T, a little speedster, or even an A with a V8-60 or the original 4 Cylinder Banger you could get away with thinner wall tubing to save some weight, but you can’t go wrong with the heavier wall tubing.

With my tubing laid on the table I decided to start from the front of the chassis and work my way back. I started by putting the table on a nice flat spot on the shop floor and adjusting the table until it was level everywhere. I then printed out stock Model A and 1932 Ford V8 frame specs to use for guidance when laying out my chassis.

Even though I’m going a custom route it helps to have some factory specs to go off of and keep you in check when getting started. I’m using a stock Model A front cross member so I marked and cut out the inside of the box tubing so that the cross member could slide in on each side.

I left a little bit of material in the front to add a pair of factory A frame horns.

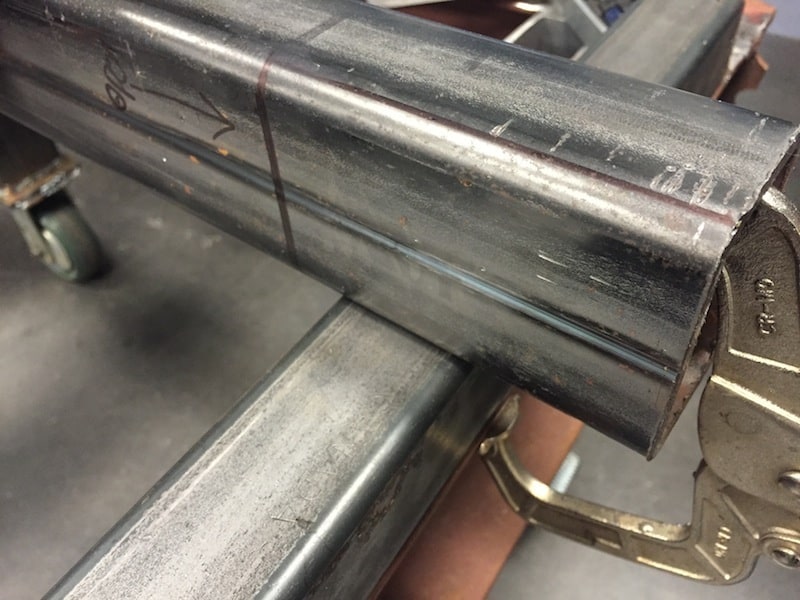

Now that my cross member could slide in and out of the rails we were ready to start setting the width of the frame and also get some measurements laid out we’d be using throughout the build. Since I’m using a factory Model A cross member I could just push the rails together so they sandwiched the front cross member and we were on the money for the frame width at the cross member.

From there we needed to angle the rails outward as the frame gets wider in the rear.

The important part for me here was to hit the factory width of the rails at the cowl so it slipped down tightly over them when I channeled the body. A factory frame sort of “kinks” out even further after the firewall and again at the B-pillar.

Since I’m channeling the car I wanted my frame rails to sit inboard of the inner “rocker” area of the frame more than stock so I didn’t have to cut them out of the body. Because of this, I left the frame rails continue to naturally angle out from the factory frame width at the cowl.

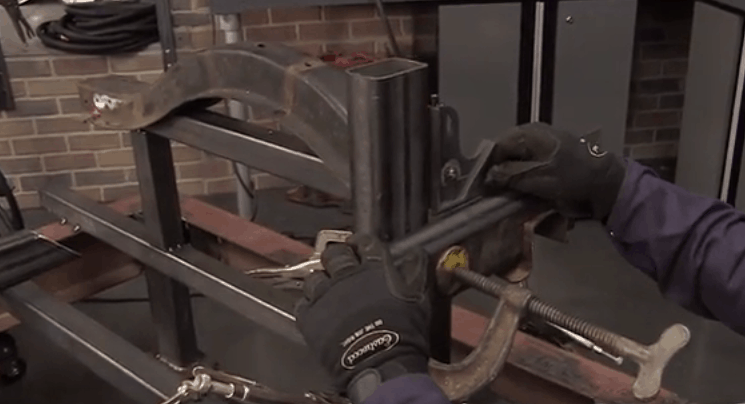

Once the rails were squared up and I was happy with the measurements, I clamped the rails down to the table and added bracing to keep the rails fixed at the width I wanted so I could fine-tune everything.

I again checked my frame rails were square with each other and the width was correct and measured out the engine bay spacing. In this case that is determined by the distance from the center of the front cross member to the firewall. Since I’m running a Flathead V8 I decided to make this area the same as a 1932 Ford V8 which is larger than a Model A. If you’re running a factory hood you will be fixed to the factory dimensions, but since I’m only running a Deuce (’32 Ford) grill that wasn’t an issue.

I marked and scribed the center lines for the firewall measurements on both sides as these would be a data line we’d use throughout the build. As silly as it may sound, these first measurements are probably the most important part of your chassis build. Just about everything you do until the car is built will be referenced off of those lines. If they’re off EVERYTHING you do will be crooked or off. Double, Triple, and Quadruple check that those suckers are dead-on!

I then clamped the cross member in place so that it was sitting with 5 degrees of caster. Ideally you should put some initial caster in here so you’re not trying to pull it all out with the wishbone angle (which also sets caster).

I again checked my measurements by measuring diagonally from the corners of the same hole on the cross member on each side and the firewall data lines we set already. Really make sure you dial this in before welding! I then welded the cross member in with the MIG 175 and we had a base to build our front suspension off of.

While I was on a roll I took a pair of factory Model A front frame horns and welded them onto to the extra material we left stick in front of the cross member. If you’re trying to stay to stock dimensions you will want to cross measure here to the factory holes on the horns. I decided to just eye ball what looked “good” to me before squaring them up and welding to the frame rails.

With the front portion of the frame started I was ready to make some modifications to get the front end of car sitting how I wanted. There’s a bunch of ways to get the front end sitting lower like a “suicide” front spring perch, air suspension, or cutting and putting a “Z” in the front of the frame.

All of these methods are pretty obvious and don’t really match the look I’m going for so I decided to “sweep” the front frame rails. This method has become more popular over the years as it allows you to lower the front a little more and gives the frame a nice curvy appearance similar to that of the Ford frames a few years newer.

This isn’t the only way to lower the front more, just how I chose to do it on this build.

There’s a couple ways to do this, one of which is to take a pie cut out of the top of the frame just in front of the firewall to bring the frame up all in one spot and weld. I wanted to accentuate the sweep so I decided to space a number of thin slices across the top of the frame.

I made these slices close together at first and spread the last few apart more. I used a reciprocating saw to make clean, thin cuts. The key is to cut three of the four sides of the frame so it can flex. Once I had the cuts all made I pulled up on the frame to close up the gaps of the cuts.

This resulted in sweeping the frame up about 5 degrees. I used an angle finder on the frame to set the upward sweep the same on each frame rail. I then beveled each of the seams for proper weld penetration and tack welded each of the cuts to hold the frame in that position.

If the frame was left swept up just like this it would throw the alignment of the car all out of wack, so we need to take that 5 degree angle out at the front axle. In the first picture you can see the 5 degree sweep the frame has currently. I first added some upright braces to the front of the chassis table and tack welded the side of the rails to the uprights so when I was pushing down on the frame it stayed true.

I then took a pie cut out of the bottom of the frame rails just behind the front cross member so the frame rails were level again at the cross member. The cross member itself still retains it’s 5 degree caster as it’s already welded in place. For this portion of the project always measure off of the top of the frame rails, NOT the cross member.

I then beveled the seams and tack welded them in place. Finally I double checked all of the angles were even and welded all of the seams with the MIG 175. The result gives the frame a nice flow while sweeping up to lower the front ride height.

With the frame sweep finished in the front, we were ready to pull the front half of the chassis off of the table to start mocking up the rear ride height, wheelbase, and body channel to set the stance.

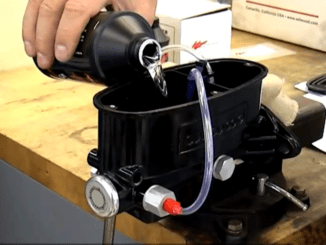

I decided to utilize a complete 1950’s “Dago” Dropped axle with “juice” (hydraulic) brakes and split wishbones I had stashed away. I removed the cobbled together front spring and installed a nice reverse eye dropped “Super Slide” spring from the guys over at Posies Rods and Customs. They were nice enough to make me a set with the ends rounded and hidden super slide pockets so that once they were painted up they could pass as an old modified part with the performance of their high-end springs.

I also mounted up the desired size wheels and tires I wanted to run on the car. These items MUST be decided ahead of time so that you can mock everything up correctly before making any major changes. On this build I’m running 750-16 in the rear and 6.00-16 in the front.

With the back half of the chassis on jack stands and leveled out I dropped the body over top of the chassis and rolled the complete rear axle with the cross member mounted to the spring under the body.

This allowed me to fine-tune the amount I wanted to channel the body over the frame. I then temporarily mounted the drivetrain to weigh the front end down to get an idea of the final front ride height. This allowed me to set the rake on the frame and body without it changing too much once the car was assembled.

Now that the body height was set and the rear wheels were sitting where I wanted (in my case I didn’t need to block them up), I took measurements from the top of the frame rails to the top of the rear cross member. This gave me a measurement of how tall my rear frame step was going to be.

I also stood back and checked to make sure the wheelbase looked good and did some minor adjustments to get the wheelbase measuring what I wanted (just slightly longer than a stock ’32 Ford V8 wheelbase). I noted all of these measurements and took everything back apart so I could mount the chassis back on the table.

After setting the chassis back on the table we used mechanics wire to cross measure where we’d be cutting the back half of the frame for where the rear step would start. I chose to make it start just behind where the rear firewall would be so that when the car was closed up you wouldn’t see the large step (but we did lose most of our trunk space).

I cut 45 degree angles into the rails at these measurements and tack welded the entire chassis to the table so it would’t move during this process.

We then took our frame rail to rear cross member measurements and built a fixture that put the top of the cross member at the exact height we wanted and tack welded the cross member to the fixture. We then set the rear cross member so that it matched our wheel base and cross measured from the front cross member to the rear cross member to make sure the wheels were straight.

The fixture was then welded to the table to lock in the rear cross member. This step is important to do two or three times to make sure the vehicle drives straight and doesn’t “crab” down the road!

At this point it’s as simple as connecting the dots to make your rear frame step. I first measured out the shape of the end of the cross member into a piece of tubing and notched out the bottom of the tube so it fit over the cross member.

I then took the drops from our rear 45 degree frame cuts and clamped them in place so I could lay another piece of tubing across the cross member to see how long the leg of the step needed to be and where the pieces intersected. This allowed me to draw out the 45 degree cuts for these two pieces.

I then beveled all of the joints and clamped the pieces in place. I adjusted them one final time until the steps were even and square on both sides. With everything measuring correctly I fired up the MIG 175 and welded the rear step up and finally to the rear cross member. I will be adding wedges or braces to the corners of each joint when we tear the car down for final welding and paint prep.

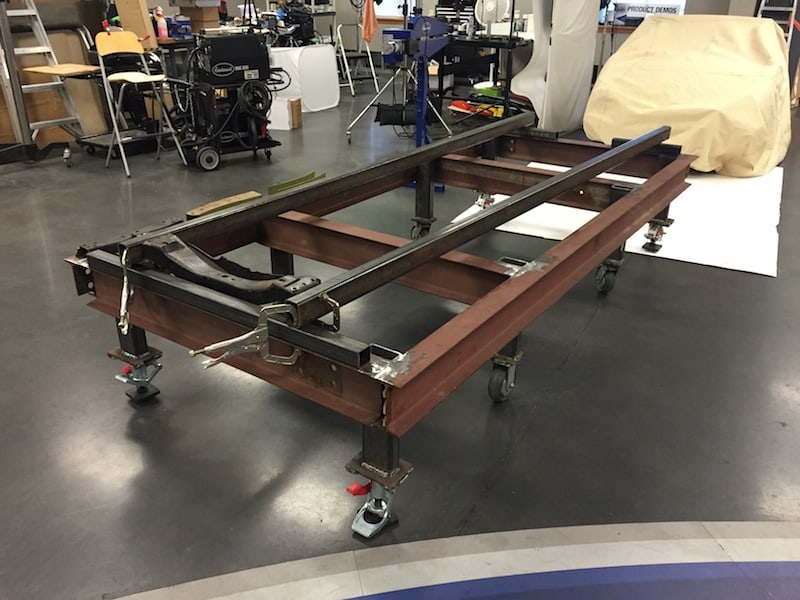

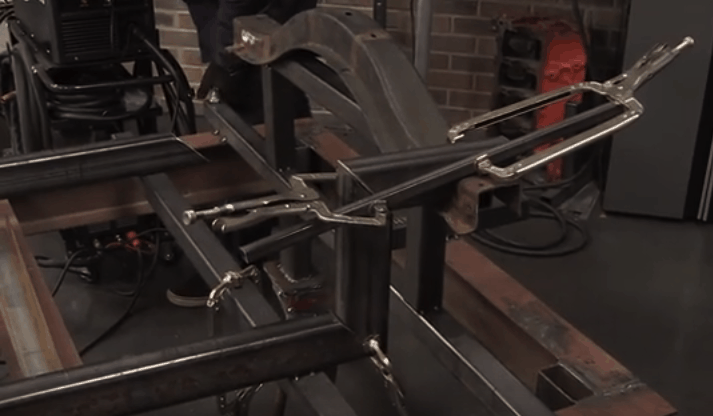

With the chassis all welded up we could cut it free from the chassis table and assemble the suspension. Of course admiring the frame only lasted for a short time before we HAD to mock the body and engine back up to really get a good look at how the car was going to look!

I’m really happy with how it sits and with some small adjustments as we build the floor, I think it is going to have a really great stance!

Now that the body and drivetrain are mocked up I can start making cross members, engine/transmission mounts, and radius rod mounts for the frame.

This tech article is meant to inspire and give you a jumping point for building your own chassis. Every car is going to be a little different in measurements and execution, so be sure to think it all through before you start.

Also, make sure that you’re confident in your welding skills before tackling a project of this magnitude, the aim is to build a strong AND safe vehicle!

Building a Model A Hot Rod with Matt from Eastwood

~ Matt / Eastwood