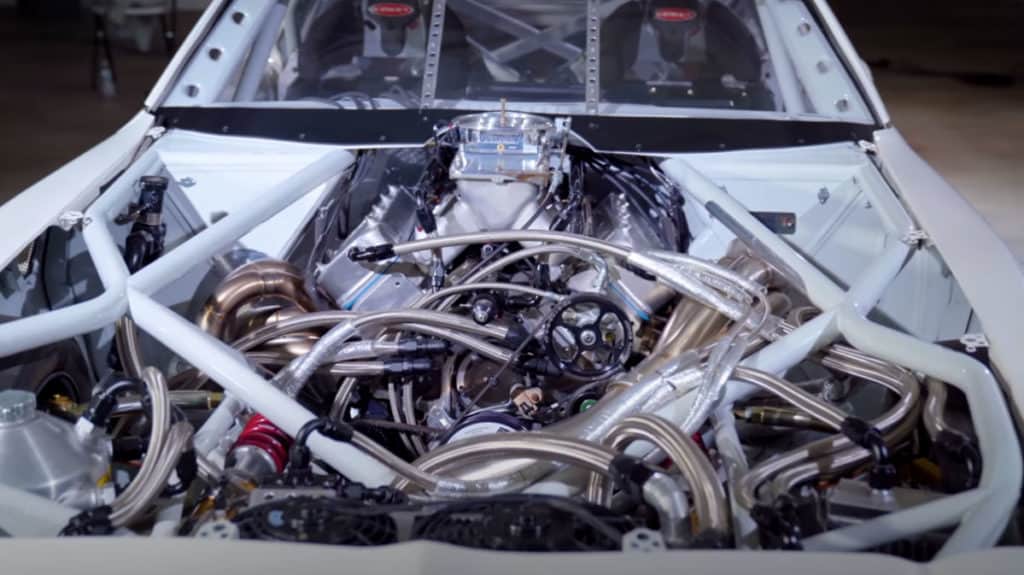

This is one of the wildest Trans Am builds ever. It has a full tube chassis, a Chevy LSX that revs up to 10,000 RPM, and makes over 1,000 horsepower.

You may have seen this Pontiac a few years ago when it debuted at The SEMA Show, but Riley Stair, the mastermind behind this car, is still tinkering with it to this day.

From The crazy engine to the THICC wheels, we’ll show you why this Trans Am one of the most cohesive and well-put-together builds we’ve seen!

Chassis / Suspension

- Entirely TIG-welded, noded, space frame chassis. Steel body

- Hand build IRS and IFS, built to exhibit correct suspension geometry at the desired ride height of 2”

- Hand built control arms front and rear

- Zinc plated suspension arms, bellcranks, rear differential cradle, sway bar arms, and motor mounts, custom rear knuckles to house 5 on 5 drive hubs.

- Coleman 2” snout modular spindles and PCR 5 on 5 race hubs up front.

- Speedway engineering adjustable splined sway bars front and rear

- Custom inboard pushrod front and rear suspension, utilizing custom Performance Shock Inc Built —-Ohlins TTX36 double adjustable coilovers with Eibach ERS springs

Steering

- Custom Woodward steering quick ratio power steering rack and remote steering reservoir and safety column/QR

- PSC power steering pump w/ remote res

- Momo Prototipo steering wheel

Engine / Drivetrain

- Motor Machine in Carmichael CA built 400ci LSX Dart LSNext2 Block, Dart 368cc 10* canted valve heads, loaded with victory titanium valves, PAC springs, w/ ti retainers, .970 solid roller lifters, custom tapered 7/16 pushrods, custom ground Cammotion billet camshaft, Jesel shaft rockers, Jesel belt drive, Billet no drill balance Callies crankshaft, GRP aluminum rods, One-off 16.25:1 Compression JE pistons, Arp fasteners throughout

- FAST 4500series thin throttle body mounted atop Dart intake, made specifically for their canted valve heads (necessitated by their reversed intake and exhaust ports, negating any other intake fitment)

- 5 Stage ARE dry sump pump, 4 gallon Peterson oil tank, ARE remote oil filter housing, Vibrant performance vent can.

- All fluids throughout the entire car exclusively plumbed with Vibrant performance -AN lines and fittings.

- Custom G Force CV axles

- RTS built Winters Quick change differential (currently 4.12 ratio)

- Custom Fuel Safe fuel cell, featuring bonded collector at pickup in Alcohol safe FIA SFI approved bladder.

- Dual Aeromotive Eliminator fuel pumps, feeding straight Methanol through Aeromotive fuel filter, to Holley EFI fuel rails, into Holley 225lb alcohol safe injectors.

- Exhausted via a pair of 4-to-1 headers, built to true equal-length with equidistant steps, built to engine specifications. Transition to dual 4″ ovals and into the 2×14” side exit exhaust protruding through the passenger door. The entire system is fabricated exclusively out of Vibrant Performance ready to weld stainless steel “U” and “J” bends.

- TEX T101a 4 speed dog box from NASCAR cup car, with DEI shifter assembly.

- 1350 spicer U jointed custom driveshaft with Sonnax Chromoly slip

- 5.5” sintered metallic, triple-disc quartermaster clutch and starter ring assembly, with quartermaster aluminum bell housing and reversed mount starter.

Body

- Media blasted, stripped to single-layer shell

- All rust repaired with replacement panels and TIG welded in.

- Body affixed to finished chassis, at which point the entire car was powder coated light gray by Performance Powder Coating and Stripping in Orangevale CA.

- New bumper, tail lights, marker lights, new chassis/body wiring harness, new tail light filler panel, new lettering, new sill plates, new door handles, new locks, new strikes, new functioning latch assemblies, new weather stripping, new windlace, new grilles, new vents, etc.

- Front T/A fender vents moved back 4.75”

- “Shaker” hood scoop moved back to the rear of the hood to match engine set back

- All metal fender flares

- Aluminum air dam

- Side exit exhaust out the passenger door

- Capped door tops where window tracks used to exist (gutted doors with dimple died frames = no windows anyways)

- Bead rolled aluminum firewall panels

- Painted Ermine white

- Lexan front and rear windows, with aluminum stiffening ribs

Brakes

- Tilton 5/8 and 3/4 master cylinders

- 2 piece slotted vented rotors, AP 6 piston front, and 4 piston rear calipers, hand made aluminum shrouded brake ducts.

- Front brakes ducted from the front valance, connected to front brake duct shrouds via Vibrant Performance HD Clamps for easy removal

- Rear brakes ducted through NACA ducts in the rear window

Cooling

- Allstar large oil cooler for engine oil

- Allstar rear oil coolers (1 for differential fluid, fed by Tilton pump, one for transmission, fed by second Tilton pump) mounted horizontally and fed via NACA ducts in the rear window, affixed to custom cooler hats via 3” Vibrant Performance HD clamps for easy removal for servicing, etc.

- Water is cooled via dual “V mounted” Chase Bays tucked civic radiators. Due to the height restrictions of the nose of the car, that was the only way to get enough core into the car to cool the power plant efficiently.

- Rads are fed with Meziere remote electric water pump

Interior

- Kirkey Full containment Driver seat and one-off Kirkey full containment Passenger seat

- Bead rolled aluminum interior panels, DZUS fastened for removal to access drivetrain and wiring/plumbing, etc.

- Hurst 10” shift selector rod

- Rennstall shift knob

- MOMO Prototipo steering wheel

- Woodward steering column

- Woodward steering QR

- Holley digital dash

- ARC switch panels

- Holley Dominator ECU mounted atop the dash

- All wiring disconnectable and removable via bulkhead connectors for servicing and maintenance of under panel goods.

- Holley Smart Ignition coils mounted on passenger side kick panel area to escape engine bay heat

- Simpson 7 point harnesses

- Bead rolled Aluminum door cards with Simpson door pull straps to engage factory door handles and open door from inside

- Anti Gravity Lithium 5lb battery behind the driver’s seat

- Two 5lb safecraft halon fire suppression bottles plumbed from behind passenger seat

- Tilton brake bias knob, master shut off button and fire pulls next to switch panel

- Lexan bulkhead in the main hoop to separate the driver compartment from the exposed rear section of the car. -Bulkhead fittings allow fluids and electrical to pass through lower, centermost Lexan bulkhead panel

- Tilton floor mount pedal assembly

- Howe racing brake and clutch fluid reservoirs

Wheels / Tires

Panasport C8 16×12 front and rear wrapped in Hoosier slicks, measuring 23.5x12r16 in the front and 25.5×12.5r16 in out back.